How can we help?

Please feel free to contact us.

sales@fsmglobal.com

On-demand Trailblazing Technology for Manufacturing

Manufacturing businesses today function in a highly dynamic and rapidly changing environment. As manufacturers work to differentiate themselves through products and services, the most progressive companies are making advances in field service management for manufacturing. Manufacturers are empowering their technicians with the right kind of information that can help them not just fix issues the right way every time but prevent them from happening in the first place by identifying and addressing these problems from the get-go.

To ensure customer satisfaction and improve their business’s efficiency and effectiveness, manufacturing companies need to connect with the right technology that can help them anticipate customers’ needs and respond before the competition does. By using FSM Grid’s manufacturing business management software, manufacturing companies that make heavy machinery, industrial appliances, construction equipment, and the like can operate more efficiently and have better chances of improving their bottom line. With manufacturing work order software, streamlining your process flow, managing contractors and inventories, lowering the risks of breakdowns and downtimes, and reducing costs just got easier.

Automate Scheduling and Optimization

Field service management software for manufacturing leverages smart features to automate your scheduling processes so that you don’t have to rely on manual scheduling to create an efficient field service schedule. Our cutting-edge software does all the work for you by generating an optimal schedule based on your priorities and limitations.

Optimizing and accelerating your scheduling helps manufacturing businesses comply with service-level agreements (SLAs) and minimize costs, overtime, travel times, and no-shows.

Manages Contractors

Your contracted partners need to be current and updated on work orders, entitlements, documentation, and service and equipment histories. With FSM Grid, it is possible to not just communicate and track your technicians but also manage your contractors and subcontractors in real-time.

Our manufacturing business management software can help you safely share information with your partners, get increased visibility into your contractor’s operations for accountability, and manage the customer experience.

Optimizes Inventory

FSM Grid can take your inventory management to the next level through accurate fulfillment propositions. This field service management software for manufacturing can help schedulers keep stock of inventory levels based on their production schedules or minimum stock rules. It can integrate with your billing software and help optimize inventory costs for your business.

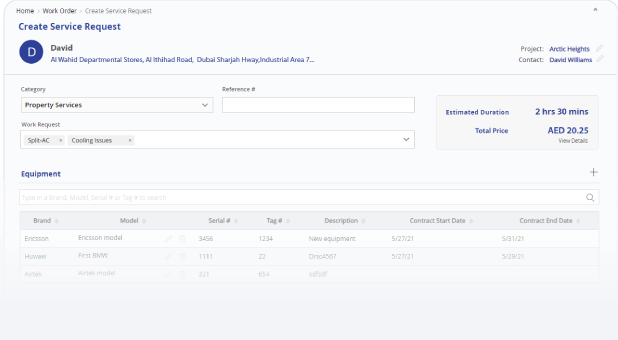

Manages

Assets

To ensure reliability and continuous uptime, manufacturers require 360° tracking and monitoring of their assets. With FSM Grid’s manufacturing work order software, we can help technicians access important information about an asset’s maintenance history, its bills, location on the client’s site, serial numbers, and attributes.

Offers Proactive Maintenance

With FSM Grid, we can help manufacturers transition from a reactive to a pre-emptive and proactive model of delivery service. Your product’s life expectancy depends on how well it has been maintained. That is why manufacturing organizations need to ensure they schedule periodic maintenance activities, so that your field service operations always run smoothly and seamlessly without risk of interruptions and delays.

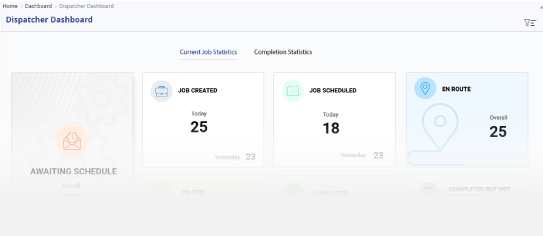

Offers Reporting

Offers Reporting

and Tracks KPIs

FSM Grid can help you get all the vital data that you need for your service’s improved performance. We can help you control your productivity with real-time equipment efficiency reports and a 360-degree dashboard that includes history, customers, and equipment visibility and monitors the losses from total productive maintenance (TPM). Our software can provide you with dynamic reports on everything for performance analysis, traceability, cost, meantime to repair (MTTR), and more.

With FSM Grid, you can create customized manufacturing business management software to monitor performance in real-time. Understanding and tracking key performance metrics in real-time is imperative for identifying your core strengths and weaknesses in your operations.

Parts

Parts

Management

One of the biggest reasons for returns is missing parts, which negatively impacts your asset time and customer experience. To avoid such outcomes, you need to get robust parts management software. While providing the right parts to technicians in the field is standard for manufacturing organizations, it is also just as important to manage reverse and depot repair processes without understocking or overstocking your inventory.

With FSM Grid, you can automate your return processes and achieve your fixed goals.

Built-In Self-Service Portal Improves Customer Satisfaction

FSM Grid high-tech/high-touch software empowers your customers to self-schedule jobs based on their time frames and requirements. No other in-field service management technology is ranked higher than FSM Grid for improving customer satisfaction.

Creating path-breaking outcomes for various industries

Latest From Blogs

How to Streamline Steel Industry Operations with Field Service Soft...April 15, 2025

The steel manufacturing sector is one of the biggest contributors to worldwide indus...

AI Copilot in Field Service Management Software: The Next-Gen Solut...January 27, 2025

Field service businesses today are evolving to stay innovative and competitive. Expl...

Give your mobile workforce the tools they need to excel

Find out how FSM Grid creates ground-breaking outcomes with high- tech/high-touch software

Download BrochureCreating A Customer First Approach in Field Operations

The field service industry has long been plagued by a persistent set of customer complaints. Many of these revolve around appointment scheduling problems, missed appointments, l...

Download